The Ultimate Guide to Extending Life Expectancy: Undercarriage Parts Upkeep Made Easy

The Ultimate Guide to Extending Life Expectancy: Undercarriage Parts Upkeep Made Easy

Blog Article

Vital Guide to Undercarriage Components for Heavy Equipment

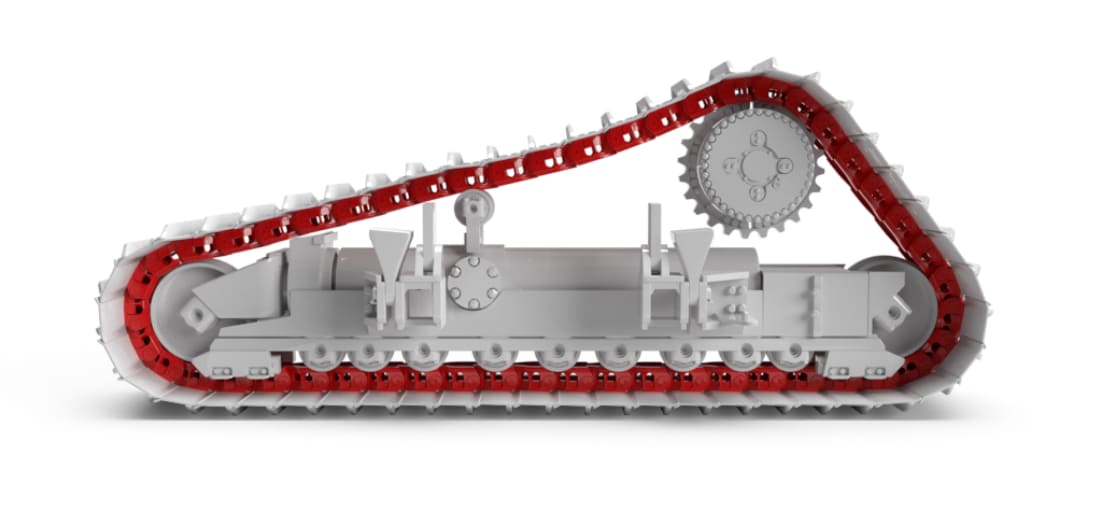

When it concerns hefty devices, the undercarriage plays a critical duty in making certain smooth and effective procedures. Recognizing the intricate information of undercarriage components is vital for maximizing the life-span and performance of your machinery. From track chains to idlers and rollers, each component contributes to the overall performance of the devices. Exploring the specifics of sprockets and various other undercarriage elements offers vital insights right into maintenance methods that can substantially affect the longevity of your hefty machinery. By comprehending the significance of these parts and their upkeep requirements, drivers can optimize the efficiency and toughness of their devices, ultimately bring about set you back financial savings and improved operational efficiency.

Relevance of Undercarriage Parts

Comprehending the crucial function that undercarriage parts play in the performance and durability of heavy devices is vital for reliable upkeep and operation - undercarriage parts. The undercarriage elements develop the structure on which the whole equipment runs, sustaining the weight of the equipment, supplying security, and soaking up shock lots during procedure. A well-maintained undercarriage not only makes sure smooth procedure yet additionally contributes substantially to reducing downtime and repair costs

The undercarriage consists of different necessary parts such as track chains, track footwear, gears, idlers, rollers, and track frameworks. The track chains and track footwear aid in supplying traction and support, while the gears and idlers aid in driving the tracks efficiently.

Types of Track Chains

Track chains are crucial components of heavy tools undercarriages, providing the required grip and assistance for reliable procedure. There are mainly 2 types of track chains used in heavy devices: secured and oiled track chains (SALT) and dry track chains.

Role of Rollers and Idlers

Rollers and idlers play a vital role in supporting and leading the track chains of heavy equipment undercarriages, adding to the total security and performance of the machinery. Idlers, on the other hand, guide the track chain and assistance keep proper tension throughout the undercarriage system.

Together, idlers and rollers function in harmony to ensure that the track chain stays in location, also on harsh surface, enhancing the equipment's efficiency and durability. Appropriate maintenance and normal assessment of idlers and rollers are vital to protect against premature wear and linked here possible malfunctions, eventually optimizing the performance and life-span of heavy equipment undercarriages.

Recognizing Sprockets

One important aspect of gears is guaranteeing proper placement and stress to avoid early wear and damage. Misaligned gears can create unequal wear on the track chain, causing reduced efficiency and prospective safety threats. Regular upkeep and evaluation of sprockets are vital to recognize any kind of signs of wear or imbalance promptly.

Furthermore, sprockets come in different dimensions and tooth configurations, depending upon the particular hefty equipment and its designated usage. Proper choice of gears based on the tools's specifications is crucial to make certain optimal performance and long life of the undercarriage system. Understanding the pop over to these guys duty of gears and their maintenance demands is essential for optimizing the performance and life expectancy of hefty equipment undercarriages.

Maintenance Tips for Durability

To ensure the extended sturdiness and optimum functionality of hefty equipment undercarriages, attentive upkeep techniques are crucial. Consistently inspecting undercarriage parts such as track shoes, rollers, idlers, and sprockets for wear and tear is important. Replace any type of worn or broken elements promptly to avoid further damage to the undercarriage system. Correct track tension modification is also vital for minimizing premature endure undercarriage components. Over-tensioning can bring about raised stress and anxiety on the components, while under-tensioning can cause track slippage and accelerated wear. In addition, maintaining the undercarriage tidy from debris accumulation, mud, and other contaminants can help avoid corrosion and extend the lifespan of the components. Oiling the undercarriage elements at suggested intervals will certainly additionally lower rubbing and wear. Scheduling normal upkeep checks with qualified professionals can determine potential concerns early on and address them prior to they intensify, inevitably making the most of the longevity of hefty equipment undercarriages. undercarriage parts.

Conclusion

In verdict, undercarriage components are vital elements for hefty devices, playing vital duties in preserving security and capability. Proper treatment and focus to undercarriage components are crucial to maximizing devices life-span and efficiency.

The undercarriage consists of various important parts such as track chains, track footwear, sprockets, idlers, rollers, and track frameworks. The track chains and track shoes help in offering traction and support, while the idlers and sprockets aid in driving the tracks smoothly (undercarriage parts). There are mostly two types of track chains used in heavy tools: secured review and lubed track chains (SALT) and dry track chains. Proper option and upkeep of track chains are crucial to ensure the overall efficiency and long life of hefty tools undercarriages

Gears are integral parts of hefty equipment undercarriages, liable for moving power from the machinery to the track chain.

Report this page